Report By: Assoc. Prof. Ir. Ts. Dr. Yeo Wan Sieng and Ts. Yung Chik Kiing, IMM-Miri Chapter Committee

Reviewed By: Assoc. Prof. Ir. Dr. Edwin Jong Nyon Tchan, IMM-Miri Regional Chapter Chairman

This one-day Corrosion and Corrosion Control Awareness for Oil & Gas Industry was initiated by the IMM-Miri Regional Chapter on 21st June 2025, and organized under the leadership of the organizing committee, namely, Ir. Dr. Christine Yeo and Mr. Yung Chik Kiing.

Institute of Materials, Malaysia (IMM) – Miri Regional Chapter successfully organized this one-day course, which was delivered entirely via Microsoft Teams hybrid mode platform by our accredited HRDC trainer, Ir. Dr. Edwin Jong.

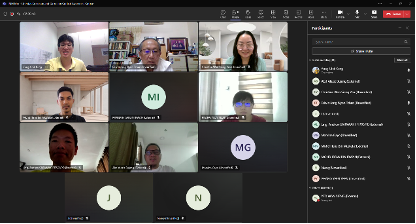

Figure 1: Group Photo session with the participants

The course as depicted in Figure 1, brought together 11 engineering participants from a variety of industries, including Oil & Gas, Palm Oil, Utilities (Electric & Water), Academia, and third-party inspection services. Attendees represented a wide range of professions, such as corrosion engineers, operations & maintenance managers, mechanical engineers, industrial inspectors, academic lecturers, and undergraduate engineering students, demonstrating the broad relevance of corrosion and corrosion control knowledge across all academic and industrial sectors.

The program was delivered by Assoc. Prof. Ir. Dr. Edwin Jong Nyon Tchan, a seasoned materials, corrosion, and welding specialist with more than 30 years of experience in the Oil & Gas industry. Ir. Dr. Edwin, who previously served with Sarawak Shell Berhad/Sabah Shell Petroleum Company, and Shell Malaysia’s Regional Deepwater Engineering Project, shared in-depth insights on corrosion mechanisms and practical corrosion control methods and techniques to mitigate corrosion in the tropical hostile marine environment.

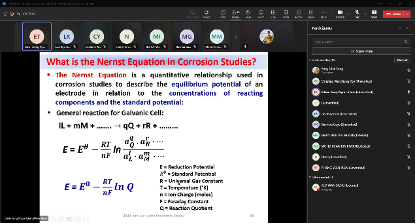

Figure 2: Assoc. Prof. Ir. Dr. Edwin is conducting the course

Key topics covered during the awareness training included

-

-

Fundamentals of corrosion, including chemical and electrochemical processes

-

Essential corrosion terminologies and predictive tools

-

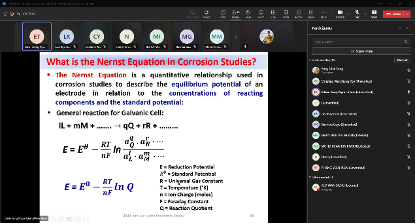

Polarization concepts and Pourbaix electrochemical diagrams as shown in Figure 2

-

Types of corrosion damage and their industrial impacts

-

Factors influencing corrosion such as pH, velocity and environmental conditions

-

Underground corrosion in buried pipelines and preventive measures

-

Principles of cathodic protection for both SACP & ICCP systems

-

Corrosion control and preventive strategies, including coatings, inhibitors, and design considerations

-

Case studies on global corrosion-related industrial incidents

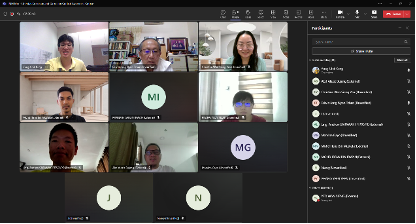

In addition to technical presentations, participants gained practical knowledge of corrosion management methods through panel discussions, where they shared workplace corrosion challenges and exchanged solutions with the lecturer/trainer and fellow attendees. This interactive approach was well-received, as it encouraged collaboration and knowledge-sharing across different industries as illustrated in Figure 3.

Figure 3: Q&A session and panel discussion

In summary, all participants agreed that the session was highly useful and informative in broadening and enhancing their in-situ working knowledge. They also expressed that the IMM-Miri Chapter would conduct more industry-related technical courses in the near future.